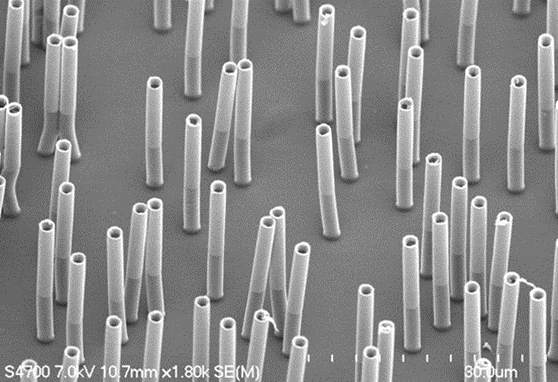

Redbud NA1 is an innovative automation platform designed for rapid nucleic acids extraction assays, capable of processing up to eight samples in under thirty minutes. Microfluidic workflows often experience prolonged reaction times due to challenges in fluid mixing within low-inertia environments. Utilizing Redbud Lab's patented micro-post technology, Redbud NA1 accelerates reactions significantly, surpassing diffusion time scales by orders of magnitude. These micro-posts operate similarly to numerous tiny stir bars, which can be controlled through a changing magnetic field. This groundbreaking technology enables the automation of industry-standard bead-based assays within a disposable cartridge.

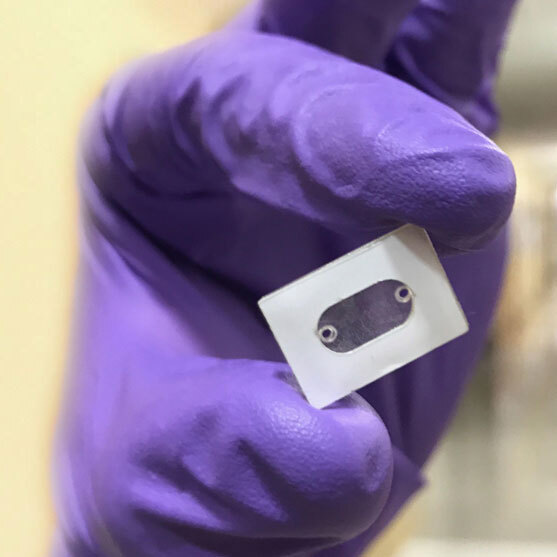

Microfluidic mixing chamber with Redbud posts

Redbud posts. SEM image

To achieve successful commercialization of this groundbreaking technology, Redbud Labs aimed to create the most reliable and user-friendly assay automation platform available. We refer to this as an automation platform because it has the potential to perform many different assay workflows in addition the the extraction assay that is runs now. Our project's objective was to provide needed automation for laboratories who normally do their extractions by hand. We noted that existing automation solutions were costly, bulky, complex, and unreliable.

Identifying a market opportunity, we established ambitious goals. Our device would cost one tenth of our competitors' prices and would not necessitate annual maintenance contracts. It would have a lifespan of 10,000 hours without the need for preventative maintenance, be compact enough to fit within a biosafety cabinet, and be the simplest machine to operate in the lab, designed with a single-button workflow that requires minimal user interaction.

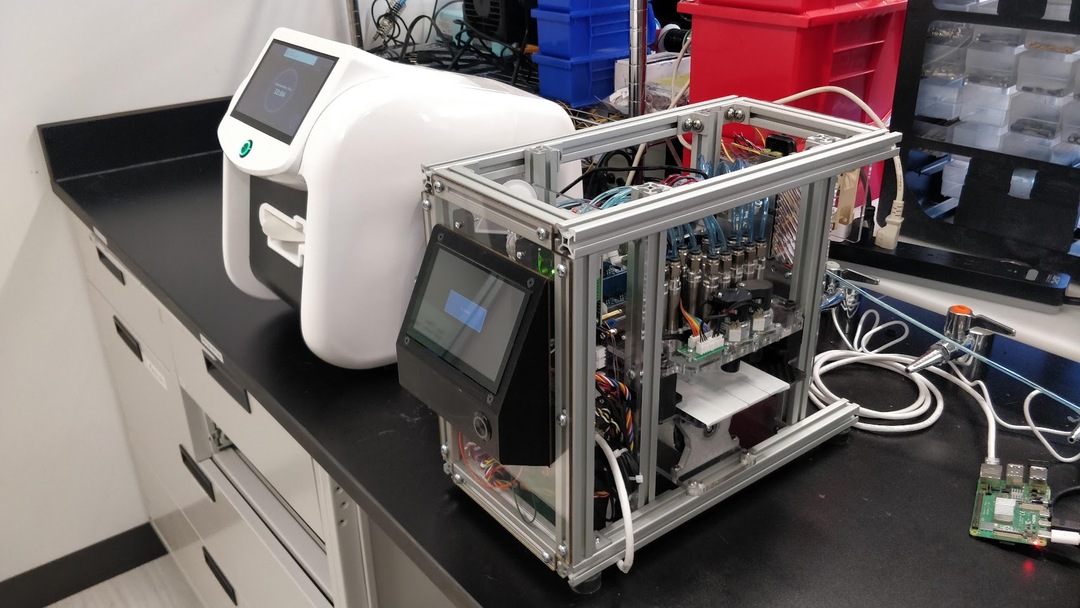

Prototyping assembly

Prototype 2 and prototype 3 of NA1

Single sample demonstration system

The instrument's function is to accept a microfluidic cartridge, inserted by the user, and to manipulate the internal fluids to replicate the steps of a manual extraction assay. The cartridge is pre-loaded with all necessary reagents, and the user adds up to eight of their own samples to the designated wells. The instrument precisely heats the reaction chamber on the cartridge and utilizes low-pressure air to circulate fluids within the cartridge. Both waste fluids and purified nucleic acids are retained in the cartridge, which is removed by the user. The extracted samples are recovered in PCR tubes and the cartridge, with the waste fluid inside, is disposed of.

As the lead design engineer, I was responsible for taking a benchtop prototype through multiple design iterations before transitioning to production with contract manufacturers. This project presented some familiar obstacles along with new challenges grew my engineering skill set. I worked to not only developed a novel laboratory device, but also create a robust library of components and methods used to interact with the microfluidic cartridge. Moving forward, we will be able to quickly adapt entirely new assay workflows to a similar instrument and cartridge setup.

8-sample microfluidic cartridge

Purified nucleic acids output from Redbud NA1